Home > Injection Mold

Plastic Injection Molding

- Product description:Plastic injection molding, custom injection mold ,injection mold produce, mold making supplier. contact us to get a free quote and a project review!

Plastics Injection Molding

Plastic injection molding is by far the most common way to produce large volumes of finished plastic parts for every kind of commercial and industrial use. we specialize in producing high-quality plastic injection molded parts and mold tools. We offer machining and finishing services to make tools from a variety of materials, and can produce 50 to 500,000+ finished parts in a wide variety of plastics.

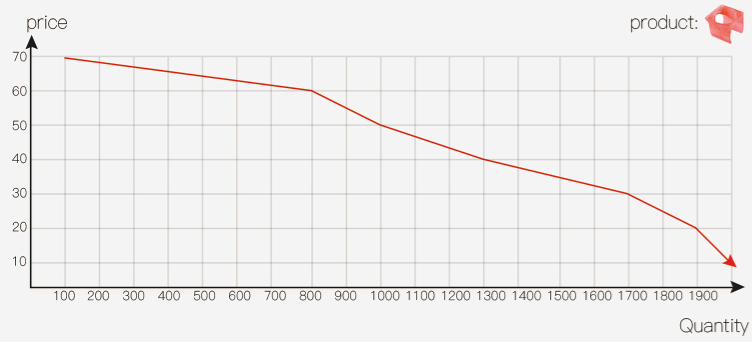

The principal advantage of injection molding is the ability to scale production an masse. Once the initial costs have been paid the price per unit during injection molded manufacturing is extremely low. The price also tends to drop drastically as more parts are produced.

At QC mold , with orders of more than 100 parts, we will consider Quick Turn Tooling, Injection Molding for plastics. we specialize in producing high-quality plastic injection molded parts and mold tools. We offer machining and finishing services to make tools from a variety of materials, and can produce 100 to 100,000+ finished parts in a wide variety of plastics.We can make rapid tooling for various plastics with different finishing, like sand blasting, texture, painting, plating and so on, depending on our customers' requirements.

Plastics Injection Materials

●Broad subcategories include commodity materials such as polyethylene, polypropylene and PVC;

●Engineering materials such as nylon, acetal and ABS for applications requiring higher performance in the areas of heat resistance, chemical resistance, impact, fire retardancy or mechanical strength.

●Other more including : Acrylic \ Liquid crystal polymer \ Long-fiber reinforced plastics \ Noryl (PPO and PS) \ Polysulfone

PC, PET, PE, PPS, PP, PS, PU, PBT, PEI, Peek , PTE, rigid and soft PVC.

Benefits of Plastics Injection

●Fillers can be used in plastic molds to increase strength

●Efficient process with very accurate finishes

●Production is quicker due to more flexibility in the molding process

●Plastic Injection molds can accommodate different plastic or polymer materials

| Make Large Volumes Fast Produce high volumes of consistent production parts with near limitiless plastic material options. |

A Wide Range Of Materials We can work with any production plastic material your project requires. |

Rapid Delivery International Express like UPS, DHL or FedEX allow us to deliver low-volume parts whitin 1-3 days. |

Quality Production Parts Get precise, repeatable parts throughout large production at the quality you expect |

We offer custom molds for plastic, rubber, and die cast component manufacturing. We create precise tools for repeatable high, medium, and low volume production runs.QC Mold professional for custom make plastic compnents protoptype, mould production,plastic parts injection based on high quality,excellent service,attractive price and promptly delivery.

Necessary Info To Get A Fast Quotation

Info In Need

Why In Need

Components File/3D Drawing

If you have 3D design, or 2D detailed drawings for

the plastic components, then it is available for getting the quotation, if you only have the plastic samples, then please do the dimension indication on the picture and send us the clear picture for getting a more correct quotation.

Plastic Material

This can help us to choose which kind of steel and which kind of injection gate

Quantity Demands

This information help us to fix how many cavities on the quoted molds. And also it help mold maker to choose the correct steel, also it will help the mold maker to optimizer your mold custom cost.

Surface Treatment

Need surface treatment or not

Molding Machine Tonnage

orInjection Capacity

This can help the mold maker to calculate the mold cavity Nr. According with your machine's size.

Are you ready to start your next project?

With advanced material verification and quality processes we can ensure your tools and parts exceed your expectations.Whether your product requires a single cavity, open and shut mould, or a complex, multi-cavity, multiple-gate, multiple-action tool, QC Mold can handle your job. Talk to one of our expert team and contact us to get your free quote.If you’re ready to start your next project, upload your product design information for a competitive injection molding quote today.

For instant quote please send your 3D drawings to info@qc-mold.com we will get back to you within 12 hours

Latest News

- How can Chinese CNC machining 2025-04-22

- Why CNC Machining is the Best 2024-08-23

- CNC Machining Cost Calculation2024-08-22

- How to Find a Manufacturer for2024-08-01

- Plastic molding: definition, p2024-07-10

Contact

CONTACT USContact:Joy Ren

Phone: +86 18598031605

Email:cillian@qc-mold.com

Whatsapp+86 18598031605

Add:No.3 Huayuan Road, Longhua District,Shenzhen,China

Eva

Eva