Electrical discharge machining

Wire EDM Shapes More Intricate Parts

What is Electric discharge machining(EDM)?

Electric Discharge Machining (EDM) is a manufacturing process that uses electrical discharges (sparks) to remove material from a workpiece. It's also known as spark machining, spark eroding, burning, die sinking, wire burning or wire erosion.

EDM is commonly used in industries where traditional machining methods are impractical or ineffective, such as aerospace, automotive, medical device manufacturing, and tool and die making. It's especially useful for machining complex shapes, hardened materials, and materials with very high strength or hardness, such as hardened steel and titanium alloys.

Industry-leading manufacturing capabilities

Wire EDM Capabilities

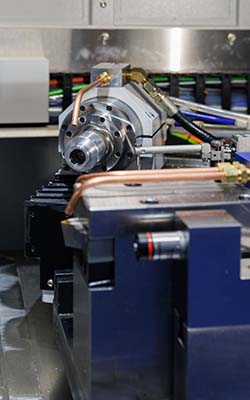

How does EDM Cutting work

It uses a thin single-strand metal wire that acts as a tool electrode to generate heat to cut a linear line through a metal workpiece. The thin wire creates an intense electrical spark that erodes the part’s material with exacting precision without physical pressure.

We use wire EDM for projects that have intricate tolerances, material stress limitations, and surface finish specifications. The number of passes to cut the workpiece affects tolerance and surface finish. More passes deliver a higher degree of precision and better finishes.

For high-volume projects with material too brittle for stamping, wire EDM offers a viable alternative. We stack work material in flat layers so we can cut through the stack for a high volume of precision parts.

Wire EDM cutting contours any conductive material difficult to shape with conventional machining techniques. Conductive metals include alloys, superalloys, steel, aluminum, brass, bronze, copper, carbon graphite, carbon steel, stainless steel, and titanium.

Why did you choose us to manufacture parts for rapid prototyping

Trusted by automotive engineers and designers from Fortune 500 companies, we provide customers with extremely low-cost automotive component processing solutions. We are your reliable partner in expert design of automotive components or specific parts, from rapid prototyping to customized production. To help you meet production requirements and industry standards, we provide solutions during the innovation phase.

|

|

|

|

|

Comprehensive Solutions |

Expertise and Experience |

Streamlined Process |

Cost-Effective and Efficient Production |

|

We offer a wide range of plastic injection molding services, all conveniently available under one roof, providing you with ultimate convenience and simplicity. Plus, with NO MOQ requirements, we’re flexible to meet your needs, whether you need a few parts or thousands. |

Our in-house team of engineers and designers boasts extensive experience and expertise in plastic injection molding. We ensure high-quality results from CAD file creation to final product completion. |

Our streamlined process focuses on clear communication, enhanced efficiency, and expedited manufacturing. We aim to make the entire process as simple and efficient as possible for our clients. |

With our advanced equipment and skilled team, we can produce thousands of identical plastic parts efficiently, reducing costs and saving time while maintaining high production rates. |

Latest News

- How can Chinese CNC machining 2025-04-22

- Why CNC Machining is the Best 2024-08-23

- CNC Machining Cost Calculation2024-08-22

- How to Find a Manufacturer for2024-08-01

- Plastic molding: definition, p2024-07-10

Contact

CONTACT USContact:Joy Ren

Phone: +86 18598031605

Email:cillian@qc-mold.com

Whatsapp+86 18598031605

Add:No.3 Huayuan Road, Longhua District,Shenzhen,China

Eva

Eva