Mold manufacturing

QC MOLD - A trusted partner in China's mold manufacturing industry

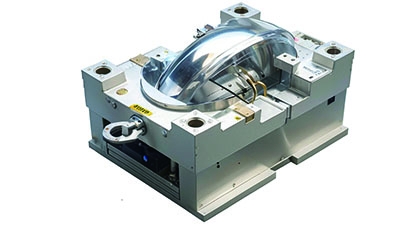

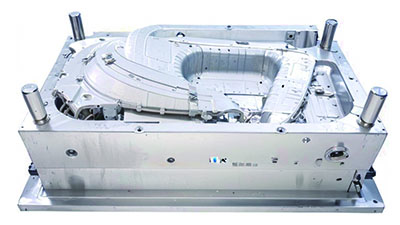

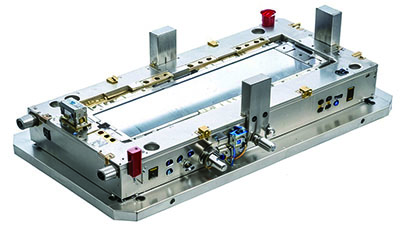

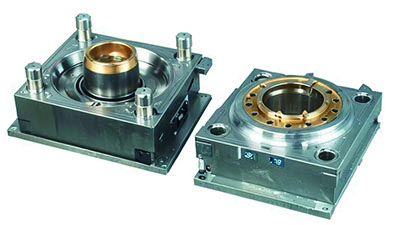

Mold is a structural component used for injection molding and compression molding of polymer composite materials. The design and geometric shape of the mold determine the shape, texture, roughness, density, and strength of future products. Molds are used for mass production of plastic products with the same structure.

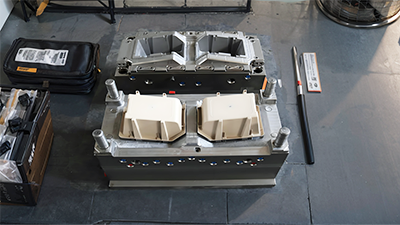

QC-MOLD focuses on mold design and manufacturing for various applications, including automotive parts, medical equipment, consumer electronics, and industrial plastic components. We have extensive experience in producing high-precision molds for automotive lighting, bumpers, decorative parts, LED lenses, medical tips, and centrifuge tubes.

Our mold capabilities

Our services

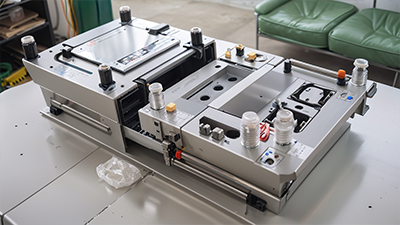

QC-MOLD purchases steel from well-known suppliers such as LKM, Gr ö ditz, and ASSAB. According to the requirements of mold manufacturing, we choose steel from the United States and Japan for mold manufacturing. Our reliable steel suppliers, skilled technicians, and advanced precision mold manufacturing equipment ensure the high quality of our molds.

QC-MOLD can produce 570 sets of molds annually, of which approximately 40% are used in the automotive industry. The remaining production capacity is dedicated to manufacturing molds for medical equipment and consumer electronics products. We are proficient in making molds for high-end car brands such as Land Rover, Mercedes Benz, and BMW.

Our engineers design plastic molds based on the characteristics of plastic parts. The types of molds we create include 2 plate molds, 3 plate molds, needle gate molds, hot runner manifold molds, thoroughly hardened molds (above 44HRC), and pre hardened molds (below 44HRC). In terms of mold manufacturing, we utilize the hot runner systems of leading brands such as DME, MOLD-MASTER, SYNVENTIVE, HUSKY, INCOE, YOUDU, SM, etc

What product molds have we made?

Why Choose qc-mold for Plastic Injection Molding Services

qc-mold delivers professional technical support with advanced injection molding services, covering material verification, tool design, prototyping & production, finishing, and quality assurance. Our team of experts is committed to achieving your manufacturing goals with precise prototypes and production parts.

|

|

|

|

|

Comprehensive Solutions |

Expertise and Experience |

Streamlined Process |

Cost-Effective and Efficient Production |

|

We offer a wide range of plastic injection molding services, all conveniently available under one roof, providing you with ultimate convenience and simplicity. Plus, with NO MOQ requirements, we’re flexible to meet your needs, whether you need a few parts or thousands. |

Our in-house team of engineers and designers boasts extensive experience and expertise in plastic injection molding. We ensure high-quality results from CAD file creation to final product completion. |

Our streamlined process focuses on clear communication, enhanced efficiency, and expedited manufacturing. We aim to make the entire process as simple and efficient as possible for our clients. |

With our advanced equipment and skilled team, we can produce thousands of identical plastic parts efficiently, reducing costs and saving time while maintaining high production rates. |

Latest News

- How can Chinese CNC machining 2025-04-22

- Why CNC Machining is the Best 2024-08-23

- CNC Machining Cost Calculation2024-08-22

- How to Find a Manufacturer for2024-08-01

- Plastic molding: definition, p2024-07-10

Contact

CONTACT USContact:Joy Ren

Phone: +86 18598031605

Email:cillian@qc-mold.com

Whatsapp+86 18598031605

Add:No.3 Huayuan Road, Longhua District,Shenzhen,China

Eva

Eva