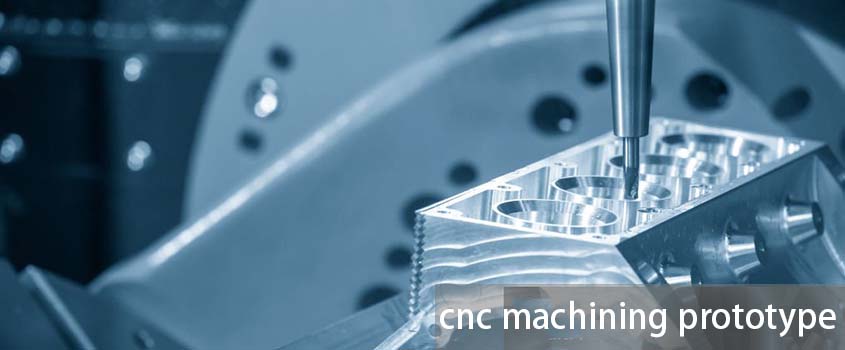

CNC rapid Prototyping China

Our Capabilities For Rapid Prototyping Machining

We are proud to have a strong network of suppliers dedicated to providing highly customized online CNC machining services to engineers, product developers, designers and other professionals. Our highly skilled machine shop is able to undertake custom design tasks from simple to complex, as well as rapid prototyping, ensuring that precision engineering needs are met.

Our product line covers multiple industries, including aerospace, automotive manufacturing, artificial intelligence and other high-end fields. The team is made up of experienced craftsmen and technicians with an in-depth understanding of materials science, engineering design and manufacturing processes. By working closely with our supplier network, we are able to ensure that every project receives the highest quality, most efficient and most cost effective solution.

Custom CNC Machining rapid prototyping Services:

|

|

|

Custom CNC Milling Services

CNC milled prototypes and production parts in days |

CNC Turning Service

CNC turned prototypes and production parts in days, Quickly test new products to reduce R&D risks and costs |

ADVANTAGES OF CNC MACHINING PROTOYPING

Ideal process prototype for CNC machining. First, the process provides a high level of accuracy and precision due to the use of computer control to supervise the movement of the workpiece and the tool. These computer controls consider every Angle of your design, ensuring that the resulting prototype is a replica of it.Rapid Prototype Parts Catalog

Another reason why CNC (Computer numerical control) is suitable for prototyping is its speed. This is completely different from processes such as injection molding, where manufacturers and product developers have to wait months until tolerances and molds are ready.

Using the CNC system, prototyping starts with creating a 3D CAD model of the final product and converting it into a CAM file. The CAM file contains the G code that controls the motion of the CNC machine during prototyping.

CNC prototyping process

|

Turning Turning is a widely used process in machining, and its core advantage is that it can provide extremely high machining accuracy and good surface finish. By rotating the workpiece and cutting with a single or multi-point tool, turning enables the precise molding of various shaft and rotary parts. Because the turning process allows precise control of depth of cut, feed speed and tool position, it is ideal for batch and high-precision machining that requires meticulous dimensional control |

CNC prototype list

Why Choose qc-mold for Rapid prototyping services

qc-mold delivers professional technical support with advanced injection molding services, covering material verification, tool design, prototyping & production, finishing, and quality assurance. Our team of experts is committed to achieving your manufacturing goals with precise prototypes and production parts.

|

|

|

|

|

Comprehensive Solutions |

Expertise and Experience |

Streamlined Process |

Cost-Effective and Efficient Production |

|

We offer a wide range of plastic injection molding services, all conveniently available under one roof, providing you with ultimate convenience and simplicity. Plus, with NO MOQ requirements, we’re flexible to meet your needs, whether you need a few parts or thousands. |

Our in-house team of engineers and designers boasts extensive experience and expertise in plastic injection molding. We ensure high-quality results from CAD file creation to final product completion. |

Our streamlined process focuses on clear communication, enhanced efficiency, and expedited manufacturing. We aim to make the entire process as simple and efficient as possible for our clients. |

With our advanced equipment and skilled team, we can produce thousands of identical plastic parts efficiently, reducing costs and saving time while maintaining high production rates. |

Latest News

- How can Chinese CNC machining 2025-04-22

- Why CNC Machining is the Best 2024-08-23

- CNC Machining Cost Calculation2024-08-22

- How to Find a Manufacturer for2024-08-01

- Plastic molding: definition, p2024-07-10

Contact

CONTACT USContact:Joy Ren

Phone: +86 18598031605

Email:cillian@qc-mold.com

Whatsapp+86 18598031605

Add:No.3 Huayuan Road, Longhua District,Shenzhen,China

Eva

Eva