Plastic Injection Molding&Mold manufacturer

Plastic Injection Molding

Plastic injection molding produces plastic parts by injecting molten plastic into a mold cavity under high pressure. It’s versatile, creating complex shapes with precision, and is widely used across industries for various products.

Transforming ideas into products

Our services

|

Plastic Injection Molding Services We offer a comprehensive range of plastic injection molding services, all conveniently available under one roof for ultimate simplicity. Our world-class services begin with the creation of CAD files. Our experienced in-house team of engineers and designers can handle this step, or you can bring your own CAD designs. |

|

|

we handle everything from manufacturing molds to completing your orders. It’s as simple as that! Our main goal is to streamline the entire process, ensuring clear communication, enhanced efficiency, and expedited manufacturing. Our plastic parts come in various colors, allowing for a wide range of finishing services and treatment options. With a single mold capable of producing over a thousand identical parts, we reduce costs, save time, and increase production rates significantly. |

|

The plastic injection molding procedure and process

1. The Design

Before your vision and ideas can be brought to light, the first thing that we have to do is create the computer files. For those who have their on-CAD files, you can just send them over and we will send you a quote within the next 24 to 48 hours.

Once all your designs have been turned into 3D files, all of your molds can be created at our CNC shop.

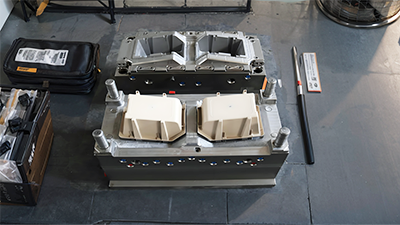

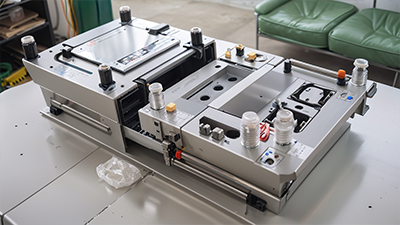

2.Mold Creation

When it comes to the creation of molds the CAD files are used, it’s important worth noting that the mold is not the final product. The shell is the final product that will be created from the mold making process.

At qc mold, all of the molds are produced in-house. Producing all of the molds will be advantageous to you as a client, the security of your design will be fully protected, it will reduce your overall cost as well as saving the production cost.

In simpler terms, the molds are hollow metal cavities that have the capabilities of producing more than a thousand identical plastic parts.

3.Injection Molding

The entire injection molding process happens very fast, the plastic pellets are injected into the mold which is in turn liquified using superheat. Once all the molten plastics have cooled, it will perfectly form all the molds producing complex shapes and geometries.

Additional layers can be added to add a bit of texture, strength, and color using a process known as over-molding. For those who don’t know much about over-molding processes, please feel free to contact our experts who will explain the process step by step.

4.Finishing and Delivery

At qc mold we have a dedicated department whose specific role and purpose is finishing services, we provide a wide range of finishing services that will not only enhance but protect all the injection molded parts.

Why Choose qc-mold for Plastic Injection Molding Services

qc-mold delivers professional technical support with advanced injection molding services, covering material verification, tool design, prototyping & production, finishing, and quality assurance. Our team of experts is committed to achieving your manufacturing goals with precise prototypes and production parts.

|

|

|

|

|

Comprehensive Solutions |

Expertise and Experience |

Streamlined Process |

Cost-Effective and Efficient Production |

|

We offer a wide range of plastic injection molding services, all conveniently available under one roof, providing you with ultimate convenience and simplicity. Plus, with NO MOQ requirements, we’re flexible to meet your needs, whether you need a few parts or thousands. |

Our in-house team of engineers and designers boasts extensive experience and expertise in plastic injection molding. We ensure high-quality results from CAD file creation to final product completion. |

Our streamlined process focuses on clear communication, enhanced efficiency, and expedited manufacturing. We aim to make the entire process as simple and efficient as possible for our clients. |

With our advanced equipment and skilled team, we can produce thousands of identical plastic parts efficiently, reducing costs and saving time while maintaining high production rates. |

Latest News

- How can Chinese CNC machining 2025-04-22

- Why CNC Machining is the Best 2024-08-23

- CNC Machining Cost Calculation2024-08-22

- How to Find a Manufacturer for2024-08-01

- Plastic molding: definition, p2024-07-10

Contact

CONTACT USContact:Joy Ren

Phone: +86 18598031605

Email:cillian@qc-mold.com

Whatsapp+86 18598031605

Add:No.3 Huayuan Road, Longhua District,Shenzhen,China

Eva

Eva