Home > Die Casting

Zin Die Casting

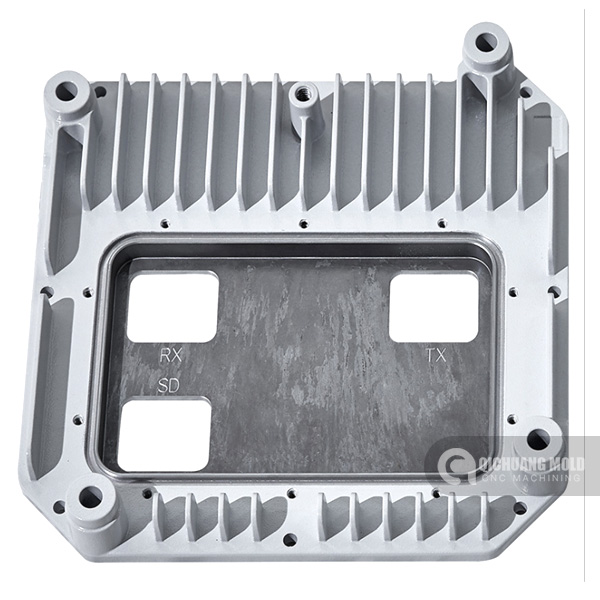

- Product description:Zin Die Casting

What is Die Casting?

Die casting is the process of producing large quantity of complex, intricate metal parts through the use of a die, a reusable mould created to the specific design of your component. In essence, this process works by pouring or injecting molten metal under high pressure into a mould cavity.After creating a specific die for the production of your part, a metal with a low melting point, like aluminium, is forced into the die and cast to create even the most complicated design, with the finished product being a part manufactured to the highest of standards.

Zin Die Casting

Zinc’s high strength and hardness lends itself to many solutions and it’s the ideal alternative to machined, pressed, stamped, and fabricated components. Zinc alloy characteristics:

●High strength and hardness

●Excellent electrical conductivity

●High thermal conductivity

●Low cost raw material

●Ability to cold form, which eases joining

●High quality finishing characteristics

●Outstanding corrosion resistance

●Full recyclability

●High dimensional accuracy and stability

●Excellent thin wall capability

DOING MORE FOR LESS

Our versatility enables us to quote competitively and cast competently, whether for long or short runs, large or small parts, simple or complex designs.

QC Mold provides superior quality custom die casting parts and components for a wide range of industries including automotive, food dairy, machinery, medical, plumbing, watering, mining, petrochemical, electrical, energy, aerospace, submarine and others.We have a wide array of die casting machines and handle many of our secondary operations in house, using our extensive machining centers. We routinely build custom machines for specific customer requirements, in order to reduce their overall costs. Our goal is to efficiently improve the functionality and manufacture ability of your designs. We offer an extensive variety of die casting, machining, and finishing operations that enable us to complete your project efficiently and economically.

Die Casting Material

Aluminum alloys that QC Mold offers including, Zamak 2, Zamak 3, Zamak 5, Zamak 7, ZA 8, ZA 27 - Zinc Aluminum, EZAC . More special material, please feel free contact our professional engineers.Advantages of Zinc Die Casting

●Great tool life

●Precision tolerance

●Superior thermal conductivity

●Fast cycle time

●Corrosion resistance

●Superior for decorative finishing

●Low energy cost

Post finishing includes blasting, polishing, plating, painting, printing, anodizing, and precision fine machining. Pressure die casting is a method of processing aluminum into engineering shapes by molding molten metal into hardened pressure die casting molds.

|

Get Your Die Casting Project Started Today With a range of finishing services to choose from and guaranteed quality thanks to our inspection services you can trust you will receive great parts every time. Once you send us your 3D CAD file, one of our customer service engineers will check your design for manufacturability to ensure that the part can be made to your expectations and budget requirements. Contact us today for a free quote! |

|

Latest News

- How can Chinese CNC machining 2025-04-22

- Why CNC Machining is the Best 2024-08-23

- CNC Machining Cost Calculation2024-08-22

- How to Find a Manufacturer for2024-08-01

- Plastic molding: definition, p2024-07-10

Contact

CONTACT USContact:Joy Ren

Phone: +86 18598031605

Email:cillian@qc-mold.com

Whatsapp+86 18598031605

Add:No.3 Huayuan Road, Longhua District,Shenzhen,China

Eva

Eva