News

Current Status and Advantages Of CNC Turning and Milling Compound Machining

What is CNC turning and milling compound machining?

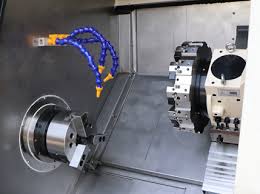

Composite processing is one of the most popular processing techniques in the field of mechanical processing in the world. It is an advanced manufacturing technology. Composite processing is to realize several different processing technologies on one machine tool. Composite machining is the most widely used and most difficult, that is, turning and milling composite machining. The turning and milling compound machining center is equivalent to a combination of a CNC lathe and a machining center. The purpose of compounding is to make a machine tool multi-functional, which can complete multiple tasks in one clamping, and improve processing efficiency and processing accuracy.

The principle of CNC turning and milling compound machining

Turn-milling compound uses the rotation of the milling cutter and the rotation of the part to realize the cutting process of the part, so that the part can meet the requirements of use in terms of shape accuracy, position accuracy, and the integrity of the processed surface. Turn-milling compound processing is not a simple Combining the two processes of turning and milling on one piece of equipment, but using the synthetic movement of turning and milling to complete the processing of various surfaces, it is a new type of cutting produced under the conditions of the extensive development of numerical control technology on the market. Theory and cutting technology.

Current status and advantages of CNC turning and milling compound machining

Development status: Most of the turning-milling compound processing is completed on the turning center, and the general turning center just replaces the ordinary turret tool holder of the CNC lathe with a turret tool holder with a power tool, and the main shaft increases the C-axis function. Due to the limitation of the turret tool holder structure and external dimensions, the power of the power head is small, the speed is not high, and larger tools cannot be installed. Such a turning center is mainly used for turning, and the functions of milling and drilling are only for auxiliary processing. Driven tool holders are expensive, causing the cost of turning centers to remain high. Most of the economical turning and milling compound are XZC axis, that is, a rotating C axis is added to the chuck to realize the basic milling function.

Advantage:

(1) Reduce processing time and improve production efficiency. Turn-milling combined processing can realize all or most of the processing procedures in one clamping, thus greatly shortening the time of product manufacturing. In this way, on the one hand, the production auxiliary time caused by the change of clamping is reduced, and at the same time, the manufacturing cycle and waiting time of the fixture are reduced, and the production efficiency can be significantly improved.

(2) Reduce the number of clamping and improve the machining accuracy. With one-time clamping to complete the production of multiple processes, there is no need for secondary clamping and special fixture production, and the processing production efficiency and the accuracy of production and processing are greatly guaranteed.

(3) Reduce floor space and reduce production costs. Although the unit price of turning-milling compound processing equipment is relatively high, due to the shortening of the manufacturing process chain and the reduction of equipment required for the product, as well as the reduction of the number of fixtures, workshop floor space and equipment maintenance costs, the overall fixed assets can be effectively reduced The cost of investment, production operation and management.

QC MOLD is equipped with more than a dozen turn-milling complex machining centers, which can meet the precision parts processing projects in various fields. If you have processing needs for precision parts,feel free to contact us for a free project review anytime at info@qc-mold.com Continue reading to learn more.

Categories

Latest News

- How can Chinese CNC machining 2025-04-22

- Why CNC Machining is the Best 2024-08-23

- CNC Machining Cost Calculation2024-08-22

- How to Find a Manufacturer for2024-08-01

- Plastic molding: definition, p2024-07-10

Contact

CONTACT USContact:Joy Ren

Phone: +86 18598031605

Email:cillian@qc-mold.com

Whatsapp+86 18598031605

Add:No.3 Huayuan Road, Longhua District,Shenzhen,China

Eva

Eva