Home > CNC Machining Parts

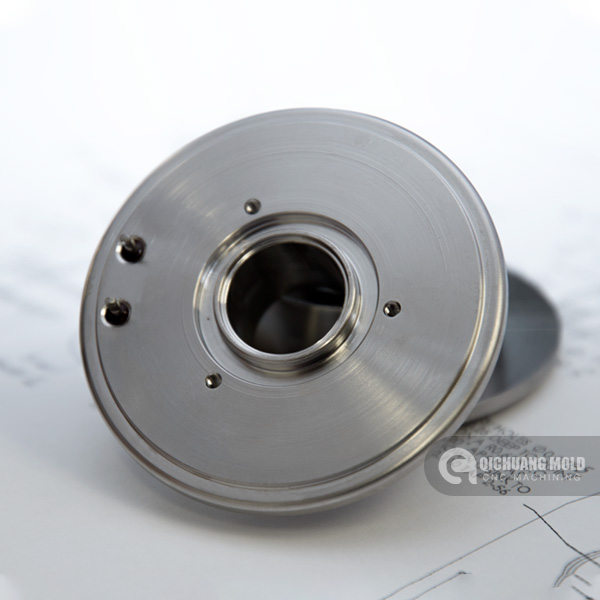

Machining Kovar

- 【Material Typr】: Controlled Expansion Alloy

- 【Material】: KOVAR/ASTM F-15/4J29

- 【Chemical Sign】: 29 Ni-17 Co-53 Fe

- 【Surface】:Nickel Plating

- Product description:Kovar Parts Prototyping And Machining, Metal Prototype Fabrication Company, CNC Machining Supplier. Upload Your CAD Or 3D Files, Get A Fast Free Quote!

Machining Kovar:

Kovar alloy is a vacuum melted, iron-nickel-cobalt, low expansion alloy whose chemical composition is controlled within narrow limits to assure precise uniform thermal expansion properties. Extensive quality controls are employed in the manufacture of this alloy to ensure uniform physical and mechanical properties for ease in deep drawing, stamping and machining.QC MOLD has the experience, knowledge, and CNC equipment required to machine a wide array of materials, including Kovar.

CNC Machining Service

At QC Mold, we use advanced equipment to offer you a variety of CNC machining services including milling, turning, EDM and wire EDM, surface grinding and much more. Using our imported 3, 4 and 5-axis CNC machining centers, our skilled machinists can make turned and milled parts using a wide range of plastic and metal materials.

Whether you require a one off model for fit and function, a small batch run for marketing and testing or low volume production QiChuang has the solution for you.

CNC Machining Materials

Metal : Kovar, Steel, aluminum, stainless steel, brass, copper, titanium etc.

Plastic :Acrylic \ Liquid crystal polymer \ Long-fiber reinforced plastics \ Noryl (PPO and PS) \ Polysulfone, PC, PET, PE, PPS, PP, PS, PU, PBT, PEI, Peek , PTE, PVC etc.

Contact us to know more about materials

We can machine virtually any engineering material, including plastics, metals and more.Whether you‘re a large corporation or a small business, we will work in a collaborative manner with you to ensure high quality.Taking your concept and turning it into reality,upload your drawings,start your free project review!

Finishing Services

Our engineers are experts in achieving the perfect finish for your product. With painting, vapor polishing, sanding, anodizing and many other services to choose from, you can create the exact look you want.

Anodizing, Painting, Pad Printing, Color Matching, Sanding and Polishing, Vapor Polishing, BlastingApplications:

Kovar alloy has been used for making hermetic seals with the harder Pyrex glasses and ceramic materials.

This alloy has found wide application in power tubes, microwave tubes, transistors and diodes. In intergrated circuits, it has been used for the flat pack and the dual-in-line package.

Preparation for Sealing:

All degreased, fabricated Kovar alloy parts should be degassed and annealed in a wet hydrogen atmosphere. Atmosphere is to be made moist by bubbling the hydrogen through water at room temperature. Care must be taken to prevent surface carbon pickup. Furnace should have a cooling chamber provided with the same atmosphere.

Heating should be conducted within the 1540/2010°F temperature range. Time at temperature should be approximately two hours for lowest temperature to 20 minutes for the highest temperature. Parts should then be transferred to the cooling zone and held until below 570°F, then removed.

An oxide film on the metallic part is preferred for metal-to-hard glass sealing. The best oxide film is thin and tightly adhering. The film can be produced by heating the parts to 1200/1290°F in regular ambient atmosphere for a time sufficient to form a dark gray to slight brown oxide.

For instant quote please send your 3D drawings to info@qc-mold.com we will get back to you within 12 hours

Categories

Latest News

- How can Chinese CNC machining 2025-04-22

- Why CNC Machining is the Best 2024-08-23

- CNC Machining Cost Calculation2024-08-22

- How to Find a Manufacturer for2024-08-01

- Plastic molding: definition, p2024-07-10

Contact

CONTACT USContact:Joy Ren

Phone: +86 18598031605

Email:cillian@qc-mold.com

Whatsapp+86 18598031605

Add:No.3 Huayuan Road, Longhua District,Shenzhen,China

Eva

Eva