Home > Manufacturing

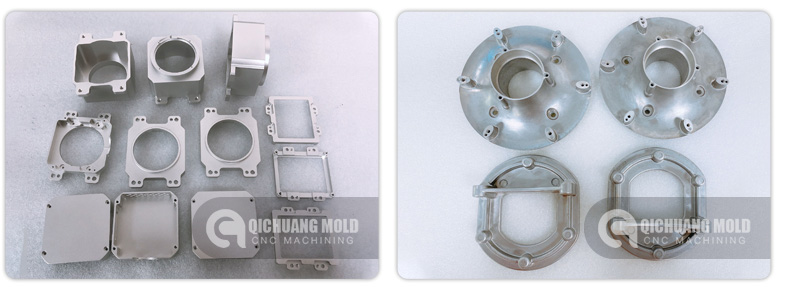

Die Casting Parts

- Process:Pressure Die Casting

- Material:Alloys Aluminum, Magnesium, Zinc

- Finish: As per customers'requirements

- ISO 9001:2015 certified factory

- Product description:QC Mold provides superior quality custom die casting parts and components for a wide range of industries including automotive, machinery, medical, plumbing, watering, mining, petrochemical, electrical

What is Die Casting

Die casting is the process of producing large quantity of complex, intricate metal parts through the use of a die, a reusable mould created to the specific design of your component. In essence, this process works by pouring or injecting molten metal under high pressure into a mould cavity.

After creating a specific die for the production of your part, a metal with a low melting point, like aluminium, is forced into the die and cast to create even the most complicated design, with the finished product being a part manufactured to the highest of standards.

Die Cast Parts for Your Industry

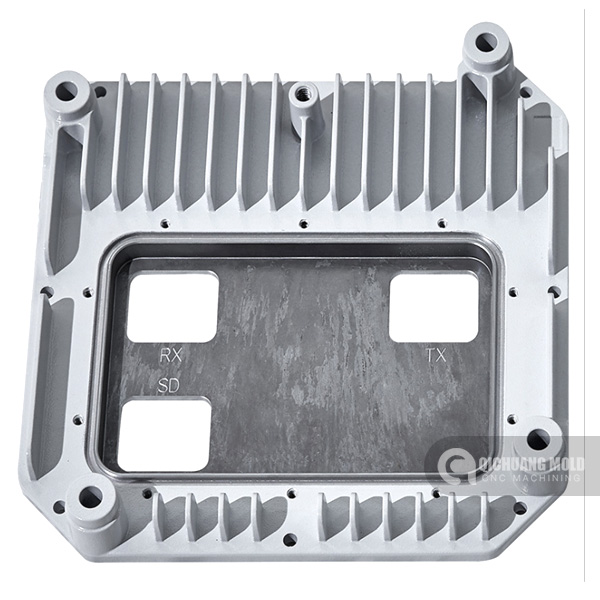

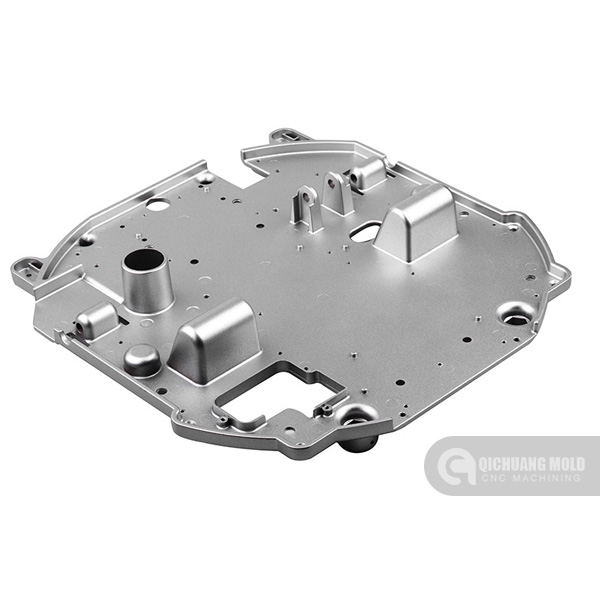

We have the capabilities to supply precision die cast aluminum parts for a wide range of industries. These include, but are not limited to, the automotive, electrical, hydraulic, industrial, lighting, and telecommunications industries. Below, you can see some examples of the export-quality parts made by our manufacturers in India. Parts can be post-machined and finished with powder coating, shot blasting, vibration, or sanding.

Similar to an injection mold, we use certified machines and

pressure casting dies to form molten metal into your designs.Our pressure die

casting process is effective and very reliable. This method can actually end

up saving your money. The majority of our castings are made from zinc,

copper, aluminum, magnesium, led, pewter or other tin based alloys.Because of

our flexibility, we’re able to accommodate any need you may have – from small

batches of 50 to up to 1000 pieces.

Benefits

● Suited for larger production runs, since die casting mold tools can be more expensive and difficult to make, price for parts produced is lower.

● Surface finish and dimensional stability are excellent

● Complex geometries can be made that require little or no post-machining

● It is great for medium to larger sized parts that would be slower and more expensive to machine

Material

QC Mold can provide Pressure Die Castings produced using hot chamber and cold chamber production die casting machines. Die cast components of any size and volume can be produced in die casting machines (“presses”) – that range in tonnage from 80T to 3500T. Machine tonnage is selected based on a number of factors including part size and cavitation - the quantity of cavities in the tool. QC Mold offers a wide range of material selection, covering but not limited to, aluminum alloys, zinc alloys, brass, copper, magnesium.

【Aluminum Die Casting】 Used to produce light but strong parts.

【Zinc Die Casting】 Zinc is used to produce ductile plated parts.

【Magnesium Die Casting】Recommended in producing light parts that require a excellent strength but keeping the weight in check.

Finishing:

Post finishing includes blasting, polishing, plating, painting, printing, anodizing, and precision fine machining. Pressure die casting is a method of processing aluminum into engineering shapes by molding molten metal into hardened pressure die casting molds.

Secondary Operations & MachiningProduction die casting tools are designed to produce components that meet dimensional requirements and the process can cast in external threads. When the finished dimensions and other features cannot be met by the casting process secondary operations are utilized to ensure specific features, areas and dimensions of the castings meet the required tolerances. Die castings are commonly drilled, tapped, reamed and are precision CNC machined to meet design criteria and dimensional tolerances required for product performance and quality.

Fields of Application

Die casting is mainly used for large series production, i.e. for many components of the same type to be cast. Despite the high pressure used during the manufacturing process, a high casting quality is achieved. The die casting process is particularly suitable for the production of very thin (up to 1 mm) (lightweight) components.Most commonly, die cast components are manufactured for the automotive industry, such as wheels, blocks, cylinder heads, valve blocks and manifolds.In addition, there are other industries in which die cast parts are used:

If you have a complex part design, we can help you turn it into a reality. With the right equipment, strong technical knowledge, and a focus on quality, we work with our ISO 9001- 2015 certified manufacturing partners to guide you through every step of the process.

● Aerospace

● Domestic

Appliances

● Furniture

● Power Tools

● Electronics

● Machinery

● Lighting Technology

Get Your Die Casting Project Started Today

With a range of finishing services to choose from and guaranteed quality thanks to our inspection services you can trust you will receive great parts every time. Once you send us your 3D CAD file, one of our customer service engineers will check your design for manufacturability to ensure that the part can be made to your expectations and budget requirements. Contact ustoday for a free quote!

Latest News

- How can Chinese CNC machining 2025-04-22

- Why CNC Machining is the Best 2024-08-23

- CNC Machining Cost Calculation2024-08-22

- How to Find a Manufacturer for2024-08-01

- Plastic molding: definition, p2024-07-10

Contact

CONTACT USContact:Joy Ren

Phone: +86 18598031605

Email:cillian@qc-mold.com

Whatsapp+86 18598031605

Add:No.3 Huayuan Road, Longhua District,Shenzhen,China

Eva

Eva